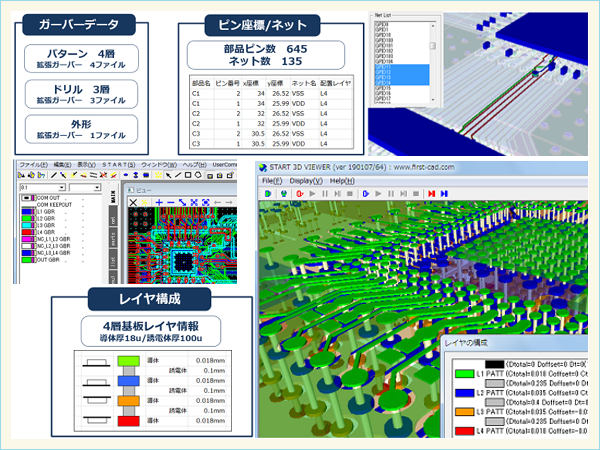

Gerber reading conversion example

Using the Gerber data for manufacturing, the 3D layer configuration and electrical connections are restored and used for simulations.

◆ step1: Restore the recognition of the wiring pattern.

Check the components of the read Gerber data, convert it to the optimum data, and perform connection recognition and gap check between layers.

◆ step2: Restoration of mounted component pin information.

Place the parts using the coordinate list of the part pins, etc., and extract the netlist.

◆ step3: Addition of 3D elements.

Create 3D data by adding thickness and attribute information to the layer.

※Please Contact us for details.